I had expected to have been finished the track work by now but progress has slowed. The inclines are trickier than I had first thought, and I've had to change the path some of them took too many times to count. I also added another way up and down so there could be two trains running simultaneously at any 1 time without too much interference.

I've also spent a lot of time investigating train detection to automate the layout with computer control - of course! Since I don't feel like ripping up the track to put in total power block isolation, I'm going to go with photo transistors. I also think that power tracking isn't the right way to do things - it feels like a left over from the DC days when you had to use power blocks. There's also better ways to do detection - sound, RFID, IR, etc. I think that the tech should not only show where things are (with an inch or two) but what the things are (loco ID's, etc) RFID can almost do this - the location aspect is difficult or so I'm reading. Photocell's can read this info as trains pass over if they've got the tech for it... just nothing right now unfortunately.

I'm still stumbling slowly forward.

Friday, December 24, 2010

Monday, November 29, 2010

Building the yard

Got some work done this past week. Its been a bit frustrating as I was waiting for bridges and was hemming and hawing over the elevation, and curves. Just thinking too many things and not doing anything. So I said 'screw it' and built the yard.

I'm now debating on whether its going to be the Kitchener Station or the Streetsville yard . Kitchener is where I was born and raised, so there's some nostalgia, but Streetsville is close to where I work now and its more a true yard (and its CP). I might put Kitchener across the table now, so I can have the best of both worlds!

The original plan has met some changes - shocker! - and due to lack of foresight on my part about cliffs and scenery and other stuff, two tracks were discarded. No big deal, they were just going to be rip tracks and engine spots. Oh and the angles on the one side are off, but it still works!

So that's the work that's been going on lately. Still having issues on where to place all the controls for the switches, as the front of this section's table has all the electrical wiring going to it. Hindsight being 20/20 it was the wrong place to put it all. Oh well.

I'm now debating on whether its going to be the Kitchener Station or the Streetsville yard . Kitchener is where I was born and raised, so there's some nostalgia, but Streetsville is close to where I work now and its more a true yard (and its CP). I might put Kitchener across the table now, so I can have the best of both worlds!

The original plan has met some changes - shocker! - and due to lack of foresight on my part about cliffs and scenery and other stuff, two tracks were discarded. No big deal, they were just going to be rip tracks and engine spots. Oh and the angles on the one side are off, but it still works!

|

| Building the yard |

|

| All put together and glued down |

So that's the work that's been going on lately. Still having issues on where to place all the controls for the switches, as the front of this section's table has all the electrical wiring going to it. Hindsight being 20/20 it was the wrong place to put it all. Oh well.

Sunday, November 28, 2010

Rolling Stock

I love to get parcels in the mail. There's just something Christmasy about it. Anyway, recently I ordered some Thomas the Train stuff from my N scale supplier, so I tacked on a few things that I needed (well, wanted is a better word). And I finally found some Rapido Via Rail cars on line from a great supplier in Manitoba (go Canada eh!? Rapido is also Canadian so its nice the total solution was sourced from here) and the more I looked at his stuff, the more I decided to buy. of course.

So in addition to 4 Via Rail cars, pictures to follow, I got 4 hopper cars from Intermodal. Ok, my thoughts on the Rapido - wow, awesome detail, nice rolling, great stuff but I expected that from their price.

The Intermodals were surprising though. Inexpensive, 15 bucks or something, but the detail and quality are top notch. Very impressive.

So in addition to 4 Via Rail cars, pictures to follow, I got 4 hopper cars from Intermodal. Ok, my thoughts on the Rapido - wow, awesome detail, nice rolling, great stuff but I expected that from their price.

The Intermodals were surprising though. Inexpensive, 15 bucks or something, but the detail and quality are top notch. Very impressive.

|

| Hoppers in action! |

|

| Going East out of Fergus's Industrial Spurs |

Saturday, November 6, 2010

Track plan revision

I've done some things here and there, but its slowed down. I'm finding that I've been thinking way to much and doing to little. So I thought I'd post this and see if I can push forward a bit.

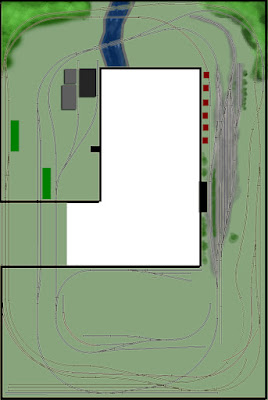

I revised the plan to include another way down from the top layer, before I had only 1 way down and no way to turn a train around. The revision allows a train to come up, make a complete loop and then descend to the bottom layer. The picture is below, the green is the top layer, about 10" above the blue.

Also a bit frustrating is my deviation from the plan ! I'm finding that I'm close in my layout but there are some serious differences. For example the Kitchener Yard - I screwed it up a bit and my two engine leads are going to have to be on the south end and not the north as on this plan. Also there are going to be some seriously steep cliffs as I don't think I thought enough about horizontal elevation changes.

I thought of a new style for my layout plan - the actual with pictures, so I tried it out with mixed results. Only the top half, I still had a few problems with skew and my angles. I think next time I'll have to rig up a fix to hold the camera vertical every time.

I hope that it will all work out in the end !

Also I'm ordering some Via Rail stuff to go with my P42 Via Rail Locomotive

I revised the plan to include another way down from the top layer, before I had only 1 way down and no way to turn a train around. The revision allows a train to come up, make a complete loop and then descend to the bottom layer. The picture is below, the green is the top layer, about 10" above the blue.

|

| Revised Track Plan |

Also a bit frustrating is my deviation from the plan ! I'm finding that I'm close in my layout but there are some serious differences. For example the Kitchener Yard - I screwed it up a bit and my two engine leads are going to have to be on the south end and not the north as on this plan. Also there are going to be some seriously steep cliffs as I don't think I thought enough about horizontal elevation changes.

|

| Prettied up in Photoshop |

I thought of a new style for my layout plan - the actual with pictures, so I tried it out with mixed results. Only the top half, I still had a few problems with skew and my angles. I think next time I'll have to rig up a fix to hold the camera vertical every time.

I hope that it will all work out in the end !

Also I'm ordering some Via Rail stuff to go with my P42 Via Rail Locomotive

Saturday, September 25, 2010

Installing a Digitrax DN163A3 into an ATLAS MP15-DC

As I pointed out in an earlier blog I've made the decision to use DCC. Well, let's be honest, it wasn't much of a decision - the advantages are legendary. However, every loco that I will be using needs to have a DCC mobile decoder in it.

One of the locomotives, the Atlas MP-15DC (a common CP Rail yard worker) was DCC ready - very confusing as it doesn't mean it can run in DCC rather it can take a DCC decoder without soldering. I purchased the Digitrax decoder and set out to install it !

Now keep in mind that I'm pretty handy with computer parts and general building etc. Back in the day I built hundreds of 486 and Pentium computers. Those were in the days of multiple jumpers, voltages and all sorts of nasty trickier with IRQ assignments etc. Then Plug and Play came along and things changed (for the better) but I digress. Suffice it to say - I'm comfortable taking things apart and putting them back together.

Being the first time for doing this I decided to read the instructions. Seemed pretty straight forward. Take the loco's case off, unscrew a couple screws, loosen the onboard DC controller remove it and then put in the new Digitrax DCC one. I studied the pictures, and the real items and thought I was ready.

Then it occurred to me - how the !#$!@ do you take the case off !? The instructions don't tell you. The little parts list that comes with the loco don't. Friends? I don't have any interested in trains. Google ? oh, yes, there's a funny guy on Youtube that shows how to use a storage case and a 2" drop to remove all manufacturer's motor cases. Real funny - worked for him, worked for me? of course not! I'm thinking that his cases were looser than a stripper in Tijuana. More googlin' , followed by more and more reading. Finally I found something ! and it worked ! you can use a tiny screw driver to loosen and pry the back off. After an hour lost and a broken handrail on the unit, I was back on track.

So now all I had to do was loosen the two screws a bit and wiggle the DC controller card out. Once again the instructions failed to mention a couple things. Like the wheels fall off as soon as you touch the screws. This was a bit surprising... then I loosened too much and the whole thing fell apart into pieces, the motor, crank shafts and all these little parts ended up on the table. The DC card was still firmly nestled in the frame though. of course. I took that out and then put everything back together with the Digitrax decoder in but I couldn't screw it together, something was out of place. I took everything apart and tried again.

Long story short, 3 hours later I had it assembled (about the 15th time) and was ready to try it out. Naturally I didn't have any track down at that time so I wired up some savage track work. Of course that didn't work until I soldered the leads to the damn track. With fingers crossed on turned it on and voila ! the light came on. Very exciting, so I gave it some power and it crawled along a bit !!!... triumphant I tried to get the case on but the frame wasn't screwed together well enough. Thinking I was an expert now, I unscrewed it and tried to figure out why the two halves weren't coming together. I re-assembled it after making an adjustment on one of the crank shaft assembly. It seemed to work - at least the shell could fit. I tried a short run with it ... but only the light went on. no power. I said some nasty things and then went to bed.

The next couple days I tried everything I could think of but to no avail. The thing just didn't want to work. So I did the only thing I could think of... I gave up until I had some bolt of lightning inspiration.

Two months passed and the LHS (local hobby store acronym) had a sale on an MP15 - not a CP but I was really only after the motor as I thought the DCC decoder wasn't working because of a grounding fault. So I picked one up.

This time I installed it the right way... and then NOTHING! I was a bit pissed - to say the least - so I took a whole lot of pictures and prepared to send them to Digitrax asking what the issue could be, thinking it might be the decoder (in all the fuss I might have smoked it). So I went to their web page and to the decoders instruction pdf (just in case). I read it. Then I looked at the picture. I looked at it again. I noticed the words that I should have seen two months ago - the LEDs go up. My board was upside down. Now its all fixed up and running beautifully.

That's my first experience with a decoder install and I'm amazed at my own stupidity. I've got another one coming up for a KATO P42 Genesis Via Rail locomotive that I can't wait to try.

Assuming I can get the case off.

|

| Digitrax DN163A3 |

Now keep in mind that I'm pretty handy with computer parts and general building etc. Back in the day I built hundreds of 486 and Pentium computers. Those were in the days of multiple jumpers, voltages and all sorts of nasty trickier with IRQ assignments etc. Then Plug and Play came along and things changed (for the better) but I digress. Suffice it to say - I'm comfortable taking things apart and putting them back together.

Being the first time for doing this I decided to read the instructions. Seemed pretty straight forward. Take the loco's case off, unscrew a couple screws, loosen the onboard DC controller remove it and then put in the new Digitrax DCC one. I studied the pictures, and the real items and thought I was ready.

|

| The Atlas MP15-DC |

Then it occurred to me - how the !#$!@ do you take the case off !? The instructions don't tell you. The little parts list that comes with the loco don't. Friends? I don't have any interested in trains. Google ? oh, yes, there's a funny guy on Youtube that shows how to use a storage case and a 2" drop to remove all manufacturer's motor cases. Real funny - worked for him, worked for me? of course not! I'm thinking that his cases were looser than a stripper in Tijuana. More googlin' , followed by more and more reading. Finally I found something ! and it worked ! you can use a tiny screw driver to loosen and pry the back off. After an hour lost and a broken handrail on the unit, I was back on track.

|

| !@##! case is off |

| ||

| Note the split in the middle - the frame is two halves with the motor nestled in the center. |

Long story short, 3 hours later I had it assembled (about the 15th time) and was ready to try it out. Naturally I didn't have any track down at that time so I wired up some savage track work. Of course that didn't work until I soldered the leads to the damn track. With fingers crossed on turned it on and voila ! the light came on. Very exciting, so I gave it some power and it crawled along a bit !!!... triumphant I tried to get the case on but the frame wasn't screwed together well enough. Thinking I was an expert now, I unscrewed it and tried to figure out why the two halves weren't coming together. I re-assembled it after making an adjustment on one of the crank shaft assembly. It seemed to work - at least the shell could fit. I tried a short run with it ... but only the light went on. no power. I said some nasty things and then went to bed.

The next couple days I tried everything I could think of but to no avail. The thing just didn't want to work. So I did the only thing I could think of... I gave up until I had some bolt of lightning inspiration.

Two months passed and the LHS (local hobby store acronym) had a sale on an MP15 - not a CP but I was really only after the motor as I thought the DCC decoder wasn't working because of a grounding fault. So I picked one up.

This time I installed it the right way... and then NOTHING! I was a bit pissed - to say the least - so I took a whole lot of pictures and prepared to send them to Digitrax asking what the issue could be, thinking it might be the decoder (in all the fuss I might have smoked it). So I went to their web page and to the decoders instruction pdf (just in case). I read it. Then I looked at the picture. I looked at it again. I noticed the words that I should have seen two months ago - the LEDs go up. My board was upside down. Now its all fixed up and running beautifully.

That's my first experience with a decoder install and I'm amazed at my own stupidity. I've got another one coming up for a KATO P42 Genesis Via Rail locomotive that I can't wait to try.

Assuming I can get the case off.

Friday, September 24, 2010

Servo's and other fun

So after a LOT of research I chose to go with the cheap servo's to control turnouts (or switches). Of course you need electronics to control them, which required more research.

http://www.tamvalleydepot.com/products/quadservodecoder.html

http://www.tamvalleydepot.com/products/quadservodecoder.html

The TAM Valley Quad servo controller

Other alternatives were offers from Hans Deloof, his has loconet support but you have to build the whole unit yourself (as in - buy the parts and solder it up)

or Team Digital's SMC4 Servo. Which is nice but expensive.

Why did I choose TAM?

Price

expandability - it has pins to allow daughter cards

already built ! Hans looked more impressive but I would have had to make it myself and I didn't feel confident of my soldering skills

Duncan from TAM Valley is very customer focused and is a great resource for questions. He's indicated that he's working on a LOCOnet daughter card which would be perfect

Until the loconet daughter card comes into being, I will have no direct feedback from my switches meaning my computer won't know if they're thrown or straight. I ordered the manual push buttons so I'll visually see which way they are but I can't write some automated train programs into my JMRI computer quite yet.

SERVO's

So although TAM Valley sells servo's for 4.5 USD, I choose to go right to the source of cheap servo's - Hobby King in Hong Kong. These guys are awesome, $2.49 for a good cheap servo with multiple arm types, 9g of power and shipping was resonable.

Now the problem is figuring out how to mount them and get my atlas switches thrown. I think this is the worst part of installation, and out of 3 installs, I've got 2 working well but I've got some ideas !! I think the problem is the depth of the tube and how I've bent the fulcrum wire, blah blah blah.

I'll put some pictures up once I have something worth showing. Until then, suffice it to say, it looks bad.

In the immortal words of Boxer (the horse) from Animal Farm

"I will work harder !"

of course, he ended up being sold to the glue factory to pay for a case of whiskey for the Pigs. mmmmm, whiskey.

Monday, August 9, 2010

Weekend work

I've gotten my track laying technique down so the pace is picking up. Just as I was starting to think that I'm going to be still laying track into 2011.

Here are my steps -

Roadbed work

So Saturday and Sunday I managed to get the Fergus industrial spurs complete.

I also fixed up some track issues on the main line, put in some more electrical feeders.

Here are my steps -

Roadbed work

- glue down roadbed (using the clear caulk)

- use a can of soup or whatever - I'm partial to a tuna can, classier I think - to roll the roadbed flat in the glue

- let it dry for a while with weights (same cans of course!)

- get the small track connectors ready - meaning that they can go onto the track tightly. I'm using the ME code 55 connectors and they're really tight, so much so that they require a bit of 'work in' before they'll go on.

- Weather the switches if they're in visible ares. I'm using the ME weathering solution. The flex track is already weathered.

- solder tracks together if its a big curve, or just a long stretch.

- fit all the pieces together, work the curves, make sure the ties are evened out after all the bending and such

- move everything out of the way, put down a thin layer of caulk.

- connect the track to the existing sections, make sure everything is ok, then put weights on the new gluing areas.

So Saturday and Sunday I managed to get the Fergus industrial spurs complete.

I also fixed up some track issues on the main line, put in some more electrical feeders.

Sunday, August 1, 2010

A short discussion on New vs Old Schools

Oh and I'm not talk break dancing.

I'm talking about controlling switches (aka turnouts), pictured below.

So old school model train people are hooked on these things called Tortoises

The new school is moving to Servo's.

So what's the difference?

Well, it cost me 2.49 cents for 1 servo made in China, shipped from Hong Kong. A tortoise costs about $15-20. Of course both require something to control them via the DCC control bus. Either way its about 6 bucks per switch. So my cost per remote controlled switch is roughly $9 using servo's, vs $24.

My question is why on earth would anyone use the old ways anymore? I've noticed that most of the guys doing MR are very very very very very conservative. There's some great wars on the forums when people bring up the future. Its a hoot listening to the old curmudgeons arguing that they 'don't need no new fangled devices' 'DC is still the best, 'cause why would you want to control more than 1 engine? crazy young whippersnappers'

Couple of the 50 servo's I got from Hong Kong. I'll put another post up on how I'm controlling them and the products I decided to use.

Now I'm off to perfect my moonwalk.

Oh and I'm not talk break dancing.

I'm talking about controlling switches (aka turnouts), pictured below.

So old school model train people are hooked on these things called Tortoises

The new school is moving to Servo's.

So what's the difference?

Well, it cost me 2.49 cents for 1 servo made in China, shipped from Hong Kong. A tortoise costs about $15-20. Of course both require something to control them via the DCC control bus. Either way its about 6 bucks per switch. So my cost per remote controlled switch is roughly $9 using servo's, vs $24.

My question is why on earth would anyone use the old ways anymore? I've noticed that most of the guys doing MR are very very very very very conservative. There's some great wars on the forums when people bring up the future. Its a hoot listening to the old curmudgeons arguing that they 'don't need no new fangled devices' 'DC is still the best, 'cause why would you want to control more than 1 engine? crazy young whippersnappers'

Couple of the 50 servo's I got from Hong Kong. I'll put another post up on how I'm controlling them and the products I decided to use.

Now I'm off to perfect my moonwalk.

More Trackwork

A brief history of trains (mine at any rate)

When I first put track down 12 years or so ago, I did what I was told by the LHS guy (local hobby store - you have to acronym-ize everything you know). He and I worked out a trackplan based on Flex track (the Code 80 stuff) that could be expanded and would be pretty easy for me to do. So the theory went! This was back in the days of DC... DCC was around but was in its earliest incarnation and expensive.

DC vs DCC

Ok, real short chat about these two words. DC is direct current and is the original way toy trains were made. The voltage on the rails tell the train how fast to go, more juice the faster the little engine spins. So if you wanted to run two engines they would run at the same speed. The only way to control multiple engines at different speeds was complicated "power zones" and you could still only have 1 independent engine in each zone. Very sucky. DCC changed all that. Every engine could be controlled individually and a few other perks since they all had microprocessor controls and such.

Here's a picture of what I'm talking about. This is my MP-15 switcher taken apart. You can see a green line on the engine. That's a DC controller circuit board. The next picture below is a Digitrax DCC controller board]

Right back to the story of my first layout! DCC was new but was expensive so I went DC. With the trackplan in mind I purchased everything he suggested. Then I got to work. Boy was that an interesting experience. I used nails to put the track down - holy crow that was nuts! I also didn't know the trick about laying track around curves. That really ticked me off. I ended up with piece of track that stopped right in the centre of the curve. I had to fasten a new piece onto it - had to match the curves and then get the little things to align. Oddly enough it didn't come out at all! So I had a track that my train couldn't use. Took the wind out of my sails a bit you know? If my terrain didn't turn out so damn good I'd probably have given up. but that's another story, let's get back to track laying.

And Now...

I spent a long time reading stuff on the internet. Apparently there's all sorts of stuff on the internet ! some of it is actually really useful. Anyway, learned some tips and tricks to laying track, and all that.

I'm using a non silicon clear chalk to stick the roadbed down, and then the track on top. No stupid little nails, which really means I wasn't playing meat tenderizer to my fingers this time around. That and it takes a lot less time to get the track down. Oh and mistakes - seriously, I've made 1 or two - are pretty easy to fix.

This picture is the mainline at zero elevation going into the Fergus station (which will be on the right), it will also be used as a siding if passing is necessary. I just got this down, looks great I think.

When I first put track down 12 years or so ago, I did what I was told by the LHS guy (local hobby store - you have to acronym-ize everything you know). He and I worked out a trackplan based on Flex track (the Code 80 stuff) that could be expanded and would be pretty easy for me to do. So the theory went! This was back in the days of DC... DCC was around but was in its earliest incarnation and expensive.

DC vs DCC

Ok, real short chat about these two words. DC is direct current and is the original way toy trains were made. The voltage on the rails tell the train how fast to go, more juice the faster the little engine spins. So if you wanted to run two engines they would run at the same speed. The only way to control multiple engines at different speeds was complicated "power zones" and you could still only have 1 independent engine in each zone. Very sucky. DCC changed all that. Every engine could be controlled individually and a few other perks since they all had microprocessor controls and such.

Here's a picture of what I'm talking about. This is my MP-15 switcher taken apart. You can see a green line on the engine. That's a DC controller circuit board. The next picture below is a Digitrax DCC controller board]

Right back to the story of my first layout! DCC was new but was expensive so I went DC. With the trackplan in mind I purchased everything he suggested. Then I got to work. Boy was that an interesting experience. I used nails to put the track down - holy crow that was nuts! I also didn't know the trick about laying track around curves. That really ticked me off. I ended up with piece of track that stopped right in the centre of the curve. I had to fasten a new piece onto it - had to match the curves and then get the little things to align. Oddly enough it didn't come out at all! So I had a track that my train couldn't use. Took the wind out of my sails a bit you know? If my terrain didn't turn out so damn good I'd probably have given up. but that's another story, let's get back to track laying.

And Now...

I spent a long time reading stuff on the internet. Apparently there's all sorts of stuff on the internet ! some of it is actually really useful. Anyway, learned some tips and tricks to laying track, and all that.

I'm using a non silicon clear chalk to stick the roadbed down, and then the track on top. No stupid little nails, which really means I wasn't playing meat tenderizer to my fingers this time around. That and it takes a lot less time to get the track down. Oh and mistakes - seriously, I've made 1 or two - are pretty easy to fix.

This picture is the mainline at zero elevation going into the Fergus station (which will be on the right), it will also be used as a siding if passing is necessary. I just got this down, looks great I think.

Sunday, July 18, 2010

Stories from the Track

The first day I had to lay some track went really really slowly. I had my cork put down with 12 year old white glue. Yup, 12 years old, still worked fine. Impressed me too. The cork was a 4' by 2' sheet that I got from Michaels Art store. Its 1mm lower than 'normal' track cork.

I suppose I should take this time to point out what cork is, why I'm using it and alternatives. Cork, not to be confused with the city in Ireland (which coincidentally I've been to) is used in MR to create a sub-road bed. Real railroads are built on beds of gravel to control water drainage, just like car roads. Ok I'm over simplifying the building process, but that's it. Water control. Except a railroad has to deal with massive weight at great speeds. The speed makes things rattle and move, not great from an engineering perspective. Wooden ties are great for keeping vibrations down, though there are new cement ones now that work and are better. wow do I get off topic.

The cork for model railroads is used for two main reasons - 1) to give the bevel effect so that it appears that its real and 2) to dampen the noise of the trains running on bare wood - again realism.

There are options - not use anything, use foam board instead of traditional lumber as the base for everything or use a foam subroad replacement.

I went with cork. So I bought two types, one for the 'yard' layout, that's the big sheet since there's a lot of track in the space and the stuff that goes under the track when it leaves the yard.

Here's a picture of the second type, the one specifically made for N scale track.

I've since discovered that I bought way too much of the one and not enough of the other. Naturally.

I spent a couple hours aligning my first track bits, re-doing it, checking, measuring over and over again. Then glued it down. Then I realized that I didn't think about my under the table servo that would operate the switches automatically. Drat. and my servo's were still being shipped from Hong Kong (2.49 each thank you very much!) so I didn't know what or how much clearance they'd need. So I dithered a bit for the next week, got another three or four feet of track down while I waited.

All in all felt super unproductive.

I suppose I should take this time to point out what cork is, why I'm using it and alternatives. Cork, not to be confused with the city in Ireland (which coincidentally I've been to) is used in MR to create a sub-road bed. Real railroads are built on beds of gravel to control water drainage, just like car roads. Ok I'm over simplifying the building process, but that's it. Water control. Except a railroad has to deal with massive weight at great speeds. The speed makes things rattle and move, not great from an engineering perspective. Wooden ties are great for keeping vibrations down, though there are new cement ones now that work and are better. wow do I get off topic.

The cork for model railroads is used for two main reasons - 1) to give the bevel effect so that it appears that its real and 2) to dampen the noise of the trains running on bare wood - again realism.

There are options - not use anything, use foam board instead of traditional lumber as the base for everything or use a foam subroad replacement.

I went with cork. So I bought two types, one for the 'yard' layout, that's the big sheet since there's a lot of track in the space and the stuff that goes under the track when it leaves the yard.

Here's a picture of the second type, the one specifically made for N scale track.

| |||||

| From Trains 2010 |

I've since discovered that I bought way too much of the one and not enough of the other. Naturally.

I spent a couple hours aligning my first track bits, re-doing it, checking, measuring over and over again. Then glued it down. Then I realized that I didn't think about my under the table servo that would operate the switches automatically. Drat. and my servo's were still being shipped from Hong Kong (2.49 each thank you very much!) so I didn't know what or how much clearance they'd need. So I dithered a bit for the next week, got another three or four feet of track down while I waited.

All in all felt super unproductive.

Thursday, July 15, 2010

Track work!

I have to admit that I was a bit intimidated thinking about all the track work that I have to do. Something I haven't touched in ... oh 12 years ! There's been all sorts of progress in the MR world. There's new track that looks really realistic now. After much research and reading it seemed that I should buy something called Code 55 flex track. The stuff that I was used to is now (or probably always was, I was just completely unaware) called Code 80. What the hell does that mean you ask. Its the height of the track... 55 is more realistic and is much lower. Here's a pic. 55 is on the left, 80 is on the right. If you look enough you'll notice it. It's more in your face if you actually see the two. Maybe I'll take my own picture, but until then here's one that kind of shows what the heck I'm going on about.

Hard to tell from the picture but 55 is all that to MR's in N scale. The stuff pictured above is KATO uni track that has a grey plastic base. Its all the rage too. Naturally, I choose differently. I'm a trend setter not a follower! Anyway, I decided to go with Atlas track - at least I did until I discovered that there isn't any to be found and they experienced a manufacturing problem in their Chinese plant. Its been about 8 months since anyone has been able to purchase it. Sucky. Its the cheapest and apparently decent. So I looked at PECO, an English brand that is based on English tie widths (ties are the thingies between the rails keeping them apart), so they don't look quite right. Then I found a lot of references to Micro Engineering and their quality product. They also made it 'weathered', meaning it looked realistic and beat up. The cost wasn't too much higher, so I got it. The switches/turnouts are from Atlas though, as they were still available and fit the ol' budget.

Anyway it really was exciting when everything showed up in the mail, totally felt like a kid at Christmas again!! Sure my visa bill was scary but heck ! that's another month away. Anyway here's a shot of me getting some track down.

You can see that I used a printout of my layout plan. I used a free (of course) program called Xtrackcad that has the ability to print 1:1, so the track was life sized. This really makes the transfer of my ideas to the actual table really easy.

Hard to tell from the picture but 55 is all that to MR's in N scale. The stuff pictured above is KATO uni track that has a grey plastic base. Its all the rage too. Naturally, I choose differently. I'm a trend setter not a follower! Anyway, I decided to go with Atlas track - at least I did until I discovered that there isn't any to be found and they experienced a manufacturing problem in their Chinese plant. Its been about 8 months since anyone has been able to purchase it. Sucky. Its the cheapest and apparently decent. So I looked at PECO, an English brand that is based on English tie widths (ties are the thingies between the rails keeping them apart), so they don't look quite right. Then I found a lot of references to Micro Engineering and their quality product. They also made it 'weathered', meaning it looked realistic and beat up. The cost wasn't too much higher, so I got it. The switches/turnouts are from Atlas though, as they were still available and fit the ol' budget.

Anyway it really was exciting when everything showed up in the mail, totally felt like a kid at Christmas again!! Sure my visa bill was scary but heck ! that's another month away. Anyway here's a shot of me getting some track down.

You can see that I used a printout of my layout plan. I used a free (of course) program called Xtrackcad that has the ability to print 1:1, so the track was life sized. This really makes the transfer of my ideas to the actual table really easy.

Foundation Continued

and now for the Benchwork

There are various types of benchwork involved in MR (that's the lingo for Model Railroading). You've got the open gridwork bench, the shelf layout, the table top style, and some hybrid. I've gone hybrid, though its mostly table top built on top of gridwork. Why? I wish I had a great reason but reality is... 'cause that's the way it turned out. Most of the layout is flat, so an open grid isn't necessary. But the raised and rising bits need, or are better suited for the grid so I've got it where I need it.

I still had my benchwork that my father and I built 12 years ago, a collection of 3 tables of open gridwork that have survived 3 house moves. That was my base around which I built the rest of the layout. Armed with a list of material needs and calculations I headed to Lowes with my father inlaw to get the goods. This required me taking the booster seats out of the CRV... never much fun but a necessary evil. Fortunately I, for once, measured properly and everything fit in and an hour later I had all the stuff into the house. That was Friday night.

Saturday and Sunday were build days. I mostly used a cheap-ass mitre saw that can't cut a staight angle to save its life. Fortunately benchwork ain't fine cabinetry, so everything (roughly) worked out.

It was actually pretty cool building it, and considering the crap tools that I had to work with, it turned out pretty damn good. Bit of self back patting there. oh did I mention everything came out level !? true.

Here are the results

2 x 4's against two walls as braces, one is lower on purpose... that section is the 'gorge' part of the Elora Gorge. You can see one of the pre-built tables on the left

There are various types of benchwork involved in MR (that's the lingo for Model Railroading). You've got the open gridwork bench, the shelf layout, the table top style, and some hybrid. I've gone hybrid, though its mostly table top built on top of gridwork. Why? I wish I had a great reason but reality is... 'cause that's the way it turned out. Most of the layout is flat, so an open grid isn't necessary. But the raised and rising bits need, or are better suited for the grid so I've got it where I need it.

I still had my benchwork that my father and I built 12 years ago, a collection of 3 tables of open gridwork that have survived 3 house moves. That was my base around which I built the rest of the layout. Armed with a list of material needs and calculations I headed to Lowes with my father inlaw to get the goods. This required me taking the booster seats out of the CRV... never much fun but a necessary evil. Fortunately I, for once, measured properly and everything fit in and an hour later I had all the stuff into the house. That was Friday night.

Saturday and Sunday were build days. I mostly used a cheap-ass mitre saw that can't cut a staight angle to save its life. Fortunately benchwork ain't fine cabinetry, so everything (roughly) worked out.

It was actually pretty cool building it, and considering the crap tools that I had to work with, it turned out pretty damn good. Bit of self back patting there. oh did I mention everything came out level !? true.

Here are the results

|

| From Trains 2010 |

2 x 4's against two walls as braces, one is lower on purpose... that section is the 'gorge' part of the Elora Gorge. You can see one of the pre-built tables on the left

Foundations

Ok, here's the first post. I'll be jotting down bits about all the fun I'm having with my trains. Naturally I've been busy with the actual doing, not so much with the documentation (that being this blog). So I've got a couple weeks, ok - months, to review.

The Planning

So I'd been tossing around a lot of various track plans and ideas. Then in the middle of my almost completed idea, there was a change of location. The empty basement apartment was re-zoned back to being a basement apartment for my uncle in law until he finds a place. Probably a year more or less. So instead of my new hobby suddenly getting - wait for it !!! -- derailed --(gosh I'm a hoot) my understanding wife said 'use the kids upstairs playroom'. Ok that reads more monstrous then it really is. The kids are 19 months old and play in the living rooms downstairs right now and will for years. Let's be honest, my progeny aren't going to be left alone in a room upstairs at least until they're 6. Even then I'm sure I'll have to install camera's to make sure that no explosives or weapons are being used.

I figure I've got 4 or 5 years before I'll have to move or re-do the layout if I go into the playroom, which is fine. I NEED to have a hobby that doesn't involve my computer (well, I do plan on automating things, but I digress) or a lot of noise after 7pm. That's bedtime for the kids. Which means that although I love pool, and would love to practise, it's unfortunately a bit loud as the billiard room is next to Greyson's room. The pool room is on the second floor of the house - unusual but that was the best spot for it.

Anyway, back to the trains - I've gone through 8 major revisions, with countless minors before deciding on this plan. During the many many hours I've spent perusing the Internet forums on N Scale trains or just model trains in general there seems to be a standard on layout designs. Its broken down into Givens and Druthers. Givens, being, well, must have's, and druthers, the rather nice to have but its ok if they never come about. So with that in mind, here are mine.

Givens

Druthers

The notes - blue is the lower or zero elevation, Green is the higher bits representing the escarpment. It will be about 12" up from the blue.

There's a red line near the bottom, that's going to be a scenic backdrop - everything behind it is going to be staging yards representing the rest of the world... so trains can go south and then new trains can come North. Maybe I'll do up a better layout diagram...

The Planning

So I'd been tossing around a lot of various track plans and ideas. Then in the middle of my almost completed idea, there was a change of location. The empty basement apartment was re-zoned back to being a basement apartment for my uncle in law until he finds a place. Probably a year more or less. So instead of my new hobby suddenly getting - wait for it !!! -- derailed --(gosh I'm a hoot) my understanding wife said 'use the kids upstairs playroom'. Ok that reads more monstrous then it really is. The kids are 19 months old and play in the living rooms downstairs right now and will for years. Let's be honest, my progeny aren't going to be left alone in a room upstairs at least until they're 6. Even then I'm sure I'll have to install camera's to make sure that no explosives or weapons are being used.

I figure I've got 4 or 5 years before I'll have to move or re-do the layout if I go into the playroom, which is fine. I NEED to have a hobby that doesn't involve my computer (well, I do plan on automating things, but I digress) or a lot of noise after 7pm. That's bedtime for the kids. Which means that although I love pool, and would love to practise, it's unfortunately a bit loud as the billiard room is next to Greyson's room. The pool room is on the second floor of the house - unusual but that was the best spot for it.

Anyway, back to the trains - I've gone through 8 major revisions, with countless minors before deciding on this plan. During the many many hours I've spent perusing the Internet forums on N Scale trains or just model trains in general there seems to be a standard on layout designs. Its broken down into Givens and Druthers. Givens, being, well, must have's, and druthers, the rather nice to have but its ok if they never come about. So with that in mind, here are mine.

Givens

- Era being modelled is post 1970's. I say that because I've aiming for anything modern, specifically after the 1990's but I have two C630's (a type of locomotive) that were discontinued shortly into the 70's in CP Rail's inventory that I rather like.

- Modelling a fictional line of CP Rail that would run around southern Ontario and the Niagara escarpment. So Hamilton, Kitchener, Waterloo, Dundas, Elora / Fergus, and where ever else I happen to like.

- All turnouts or switches on the layout are powered

- 1 mainline and ability to run a couple trains by computer without worrying about collisions (without getting into block detection yet)

- running freight and some passenger (VIA or GO, maybe both.. I know VIA is CN...)

- freight yard interchange with CN Rail, just 'cause CN is so ubiquitous in S. Ontario.

- various heights with a couple bridges and tunnels

- city scape modelling

- countryside modelling

- yard for operational fun

- hookup to the computer for automation

- DCC (digital train control, versus the really old school DC)

- Minimum 15" radius for Mainline

- Minimum 10" on side / industry spurs

Druthers

- double mainline

- signals

- train ID'ing in realtime (thinking RFID, but might have to go IR or ???)

- block detection - I haven't decided on the system but it should go hand in hand with ID's

- wireless train/layout controls with Itouch, Ipad or Iphone. Google Android is also a thought

- using JMRI or Rocrail as software controls

- webpage with ability to control layout remotely

- web cam's for 'on the scene' action

The notes - blue is the lower or zero elevation, Green is the higher bits representing the escarpment. It will be about 12" up from the blue.

There's a red line near the bottom, that's going to be a scenic backdrop - everything behind it is going to be staging yards representing the rest of the world... so trains can go south and then new trains can come North. Maybe I'll do up a better layout diagram...

Subscribe to:

Posts (Atom)